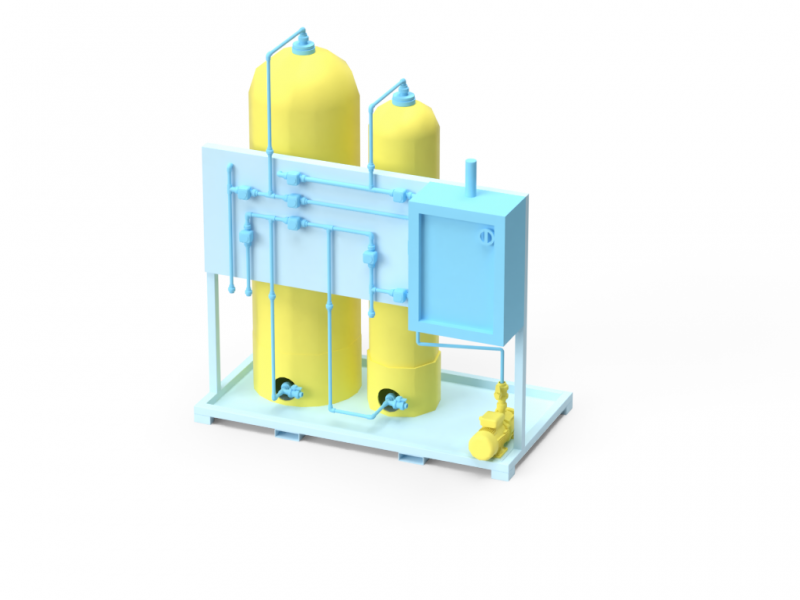

ITALPLANT builds Resin Lines for Special applications which are different from traditional Ion Exchange Resin lines due to the type of application and specific characteristics of resins used.

These plants are used to capture and/or recover heavy metals or precious metals, or for the purification of process baths from pollutants or for the treatment of groundwater contaminated by hazardous substances.

Therefore they are special plants, designed and built according to precise analytic data and supported by periodic controls and meticulous laboratory checks.