ITALPLANT also provides plants for the filtering of tap, well or industrial process water, as follows:

Filtrations

Quartz/Active carbon filtration

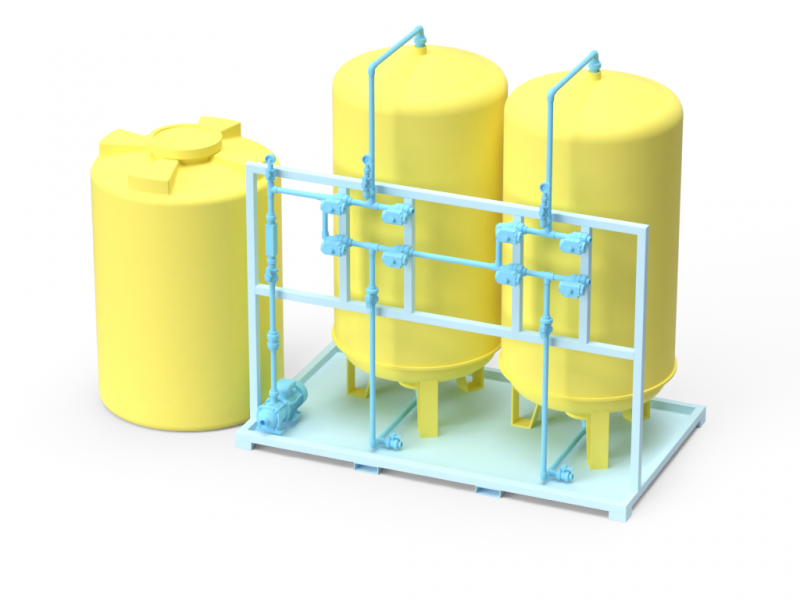

These plants consist of a column containing quartzite of varying granulometries and a column containing high-porosity active carbons with a high degree active surface.

These plants are normally used to treat inlet water for production processes or outlet waters from chemical-physical purification treatments, for the removal of solid suspended substances, surfactants, oils, hydrocarbons, organic substances, pesticides, chlorine, odours…

Filtration plants provided by ITALPLANT are built using robust fibreglass columns with inner polypropylene lining, or stainless steel columns with upper and side manholes, convenient for maintenance operations of emptying or filling with filtering material.

They are automatically operated by means of programmable PLCs which are visible in operating and rinsing phases thanks to a large touch screen panel.

Both operating and counter-washing phases are carried out using single valves manufactured in-house, which are reliable and safe, controlled and operated by means of PLC.

Bag and cartridge filtration

ITALPLANT also propose economic and easy-to-install systems for the filtration of fine or large particles, consisting of a container made from plastic material or stainless steel, inside of which one or more filtering cartridges or bag filters are installed.

Fabric or synthetic material cartridges can be installed with filtration degrees ranging from 1, 5, 10, 20, 50 , 100 microns and more, according to the type of water requiring treatment and the desired degree of filtration.

These plants can be used to filter inlet tap/well water for production processes, or installed to eliminate turbidity downstream from a chemical physical treatment plant, or to protect resin or quartz/carbon filter lines.

Self-cleaning filters

Our self-cleaning filters are compact filtering systems made from stainless steel and recommended for the removal of even coarse or colloidal suspended solids, from tap, well or industrial process water . They consist of one or more filtering elements made from stainless steel or synthetic material. The cleaning of the filtering body is guaranteed, according to the model of self-cleaning filter, by a water pressure jet washing system or by an electric motor-powered blade system, or by a combination of both systems.

The rinsing operation is fully automated and dependent on progressive filter blockage, occurring once maximum set operating pressure is reached.

Self-cleaning filters provided by ITALPLANT are fully automated, require little maintenance and are available in a range of models and operating flows.